With the exponential growth of power generation from renewable sources Voltage dips and micro interruptions are a major power quality problem and the main cause of failures and malfunctions in plants with automated processes.

VOLTAGE DIPS AND MICRO INTERRUPTIONS: DIFFERENCES

A voltage gap occurs when the residual voltage drops to between 90 and 10 per cent of the nominal voltage. The duration of the voltage hole is considered to be between 10ms up to 1 minute.

A micro-break, on the other hand, is a transient interruption and occurs when the residual voltage drops to 100 per cent of the rated voltage for a duration typically in the order of milliseconds.

These events can be caused by various sources, such as electrical disturbances, data transmission problems or electromagnetic interference.

Even if these phenomena are short-lived, they can have significant impacts on sensitive devices or critical processes, especially in areas where continuity of power supply or connection is essential.

OXYGENZERO: THE SOLUTION

Managing micro-interruptions requires the implementation of advanced protection systems to ensure system continuity and reliability.

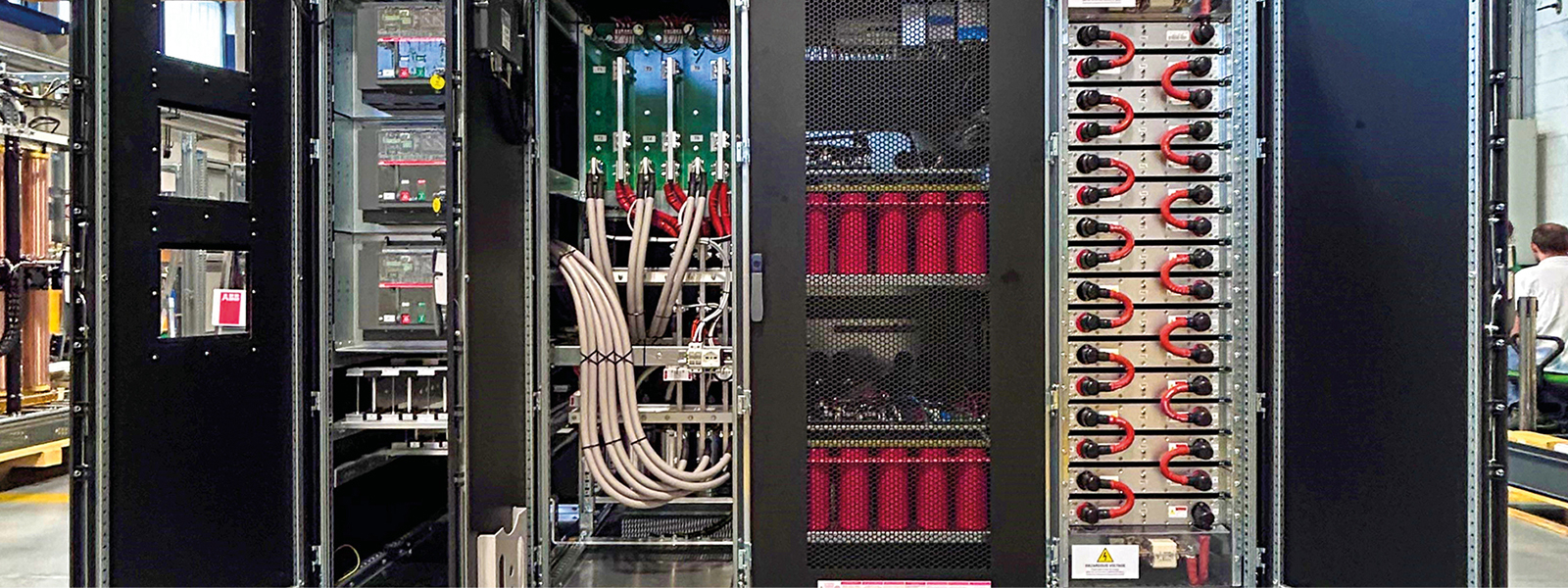

For this reason, Ortea’s design department has extended its OXYGEN range, dedicated to voltage dip compensation, with OXYGENzero, a new electronic device capable of compensating for micro power failures up to 1s at full load using energy accumulators based on supercapacitor technology.

TECHNOLOGY ADVANTAGES: SUPERCAPACITORS

- Long service life: 10 times longer than standard lead-acid batteries.

- High number of cycles: one million compared to around 300 for lead acid batteries.

- Low maintenance costs.

- High temperature resistance.

- Reduced dimensions and weight.

- Modularity: possibility of expansion to increase autonomy.

OPERATIONAL SAFETY: ADDITIONAL PROTECTIONS

- Supercapacitor protection (DC fuses: protect the supercapacitors from abnormal overcurrents by removing them from the power circuit).

- Overvoltage protection (Class II output arrester: protects the load from any overvoltage from the mains).

MAIN FEATURES

- User interface: is created using a multilingual touch display (10″). Through the selection menu it is possible to display the electrical values and set the stabiliser’s operating parameters.

- Tripping speed: thanks to an advanced control algorithm, the device is able to compensate for micro-breaks in less than 5ms.

- Mode of insertion into the system: the micro-interruption compensator is inserted in parallel with the mains.

MAIN APPLICATIONS

The following are the sectors most sensitive to the problem of micro-interruptions:

- Electronics industry (Sensitive machinery, semiconductors)

- Food & Beverage (High-speed bottling, packaging lines)

- Continuous production lines (Printing, steel mills, paper mills, petrochemicals, fibres, automotive)

- Medical (Sensitive medical equipment, hospitals)

- Pharmaceuticals (Packaging lines, continuous processes)

- Information technology (Data centres, banks, telecommunications)